Operation which can be performed on a lathe either by holding the workpiece between the centres or by a Chuck are-

(1) Turning

(2) Chamfering

(3) Threading

(4) Knurling

(5) Forming

(6) Facing

(7) Grooving

what-is-drilling-machine-and-write.

what-is-lathe-machine-give.

(5) Forming

(6) Facing

(7) Grooving

what-is-drilling-machine-and-write.

what-is-lathe-machine-give.

(1) Turning-

|

| Turning |

Turning may be defined as the machining operation for generating external surface of revolving by the

action of a cutting tool on a rotating workpiece, on a lathe (fig). For turning a workpiece, it is held either between centers or in a chuck.

Types of Turning operations -

(a) Straight Turning -

Straight turning produces a cylindrical piece of work on which the diameter is uniform in size throughout its entire length.

Straight turning produces a cylindrical piece of work on which the diameter is uniform in size throughout its entire length.

(b) Shoulder Turning -

|

| Shoulder turning |

Shoulder turning implies cutting two or more diameters on a workpiece. A shoulder is formed at the point where the size changes from one diameter to another. Fig. shows shoulder turning operation.

(c) Taper turning -

|

| Taper turning |

When the cutting move at the angle to the axis of rotation of the workpiece and produces a conical surface, the process is termed as taper turning.

Taper on a workpiece may be specified either in degree or inches per foot or in mm/metre. Taper turning has wide application in the construction of machine. Almost all machine spindle have taper holes which receive taper shank of various tools and work holding device.

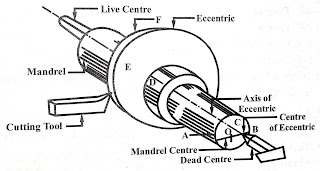

(d) Eccentric turning -

|

| Eccentric turning |

Fig shows the machining of an eccentric with a hub, D. The workpiece is mounted on a mandrel. The centres of the eccentric are laid out on both ends of the mandrel can be held eccentrically between live centre and dead centre in the table. Then the eccentric surface E and F are machined.

(2) Chamfering -

specified angle on the end of a turned diameter. This is done by removing the sharp edge. Chamfering is done by setting the compound slide at an angle and feeding the tool bit by hand to produce a specified chamfer. Chamfering removes burrs from the end of the workpiece and provides it a better appearance. A threaded job is generally chamfered so that the nut may be easily passed on it.

(3) Threading-

It is an operation of cutting helical grooves on the external cylindrical surface of workpiece. In threading, as show in fig. the work is held in a Chuck or between center and the threading tool is fed longitudinal to the revolving work. The longitudinal feed is equal to the feed of the thread to be cut.

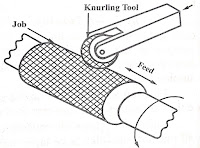

(4) Knurling-

Knurling operation produces depression or indentation of various shape in to the workpiece by the use of revolving hardened steel wheels pressed against the workpiece. Since knurling produce a roughened on a workpiece, it provides an effective gripping surface on the workpiece to avoid slipping when work by taking in hand.

|

| Chamfering |

(3) Threading-

|

| Threading |

(4) Knurling-

|

| Knurling |

(5) Forming-

Forming is the process of machining a convex, concave or of any irregular shape on the workpiece. For turning a small length of formed surface a forming tool as shown in fig. is fed straight into the workpiece. The forming tool has cutting edges conforming to the required shape. Forming is mainly a finishing operation. For sufficiently large surfaces, a straight turning tool is used. This requires both longitudinal and cross - feed simultaneously into the workpiece. This process is tedious and requires much skill. For turning a large number of wide surfaces a template having the desired shape is attached to the rear end of the lathe bed. When carriage travels longitudinally the tool will reproduce the contoured surface of the template as the guide block will trace the curved path.

(6) Facing-

Facing operation, machines the ends of workpiece. It provides a surface which is square with the axis of the workpiece from which to start the job. Facing can also decrease the length of the job. Facing is done by feeding the cross - slide or compound (by hand) in or out. In facing, the cutting tool moves from the center of the job towards its periphery and vice versa.

(7) Grooving-

Undercutting is shown in fig. It is an operation of reducing the diameter of a workpiece over a vary narrow surface. In this operation, a tool of appropriate shape is fed into the revolving work up to the desired depth at right angle to the centre ling of the workpiece.

Operation which can be performed by holding the work by a chuck or a face plate or an angle plate are-

(1) Drilling

(2) Reaming

(3) Boring

(4) Undercutting

(5)

(1) Drilling-

Drill operation is shown is fig it is an operation of making a hole in a workpiece with the help of the drill. In this operation, the workpiece is held in a Chuck and the drill is held in a tailstock. The drill is fed manually into the rotating workpiece, by rotating the tailstock head wheel.

(2) Reaming-

Reaming operation is shown in fig. It is an operation of finishing the previously drilled hole. In this operation, a reamer is held in the tailstock and it is fed into the hole.

(3) Boring-

It is an operation of enlarging of a hole already made in a workpiece. In this operation a boring tool is held in the tool post and fed onto the work by hand and power.

(4) Undercutting-

Undercutting is shown in fig. It is an operation of reducing the diameter of a workpiece over a vary narrow surface. In this operation, a tool of appropriate shape is fed into the revolving work up to the desired depth at right angle to the centre ling of the workpiece.

|

| Forming |

(6) Facing-

|

| Facing |

(7) Grooving-

|

| Grooving |

Operation which can be performed by holding the work by a chuck or a face plate or an angle plate are-

(1) Drilling

(2) Reaming

(3) Boring

(4) Undercutting

(5)

(1) Drilling-

|

| Drilling |

(2) Reaming-

|

| Remaining |

(3) Boring-

|

| Boring |

(4) Undercutting-

|

| Undercutting |

Post a Comment

Comment for more information..